How to deal with minor works so that they are installed correctly and do not pose a risk to the current installation is a key part of design control. The last thing we need is a new installation to contaminate the current system or vice versa.

What are minor works?

A reasonable definition would be anything simple in nature and does not alter the ‘footprint’ or affect the existing structure of your water system. These types of projects can vary and might include simple tap replacements, additional outlets being installed, short new pipe runs, or small refurbishments.

Water Safety Group Involvement

It is important to have the sign-off from the Water Safety Group for any new projects with buy-in at all stages of the project. This can ensure that commissioning and disinfection are planned and appropriate for the installation.

It is important to have the sign-off from the Water Safety Group for any new projects with buy-in at all stages of the project. This can ensure that commissioning and disinfection are planned and appropriate for the installation.

The commissioning of new installations should be defined in the Water Safety Plan but also be specific for each project as required depending on the complexity of the planned installation.

What options are there for disinfecting these minor works?

Is a cleansing flush sufficient or would a chemical or thermal disinfection be more suitable?

Looking to define these processes may help to decide which one would be appropriate.

According to the BSI publication PD 855468:2015 Guide to flushing and disinfection of services supplying water for domestic use within buildings and their curtilages, a cleansing flush is used to remove any debris and organic matter that may encourage the growth of biofilms, to remove any excess flux or to remove the residues of disinfection.

Mains quality water would typically be used for a cleansing flush. Disinfection is a process that renders inactive pathogenic microorganisms or parasites. A disinfection would typically be done using an appropriate chemical, chlorine-based disinfectants are popular although others exist, or thermally, using heat to pasteurize the system.

Following the guidance in PD 855468:2015; a ‘cleansing flush’ should be carried out on completion of a new water installation or refurbishment of a hot and cold-water system or on the installation of new components, especially those which have been pressure-tested using water by the manufacturer.

It, however, goes on to say that, where necessary, a ‘disinfection’ should also be carried out under the same circumstances! So, the choice of which option to take should be detailed in the project based on the type of installation. There may be instances where both are required; a cleansing flush to remove debris and then a disinfection to inactivate any micro-organisms present.

It, however, goes on to say that, where necessary, a ‘disinfection’ should also be carried out under the same circumstances! So, the choice of which option to take should be detailed in the project based on the type of installation. There may be instances where both are required; a cleansing flush to remove debris and then a disinfection to inactivate any micro-organisms present.

Part of the decision on how to ‘disinfect’ minor works should come from the manufacturer of the item being installed, as there may be specific instructions on installation and commissioning for said item.

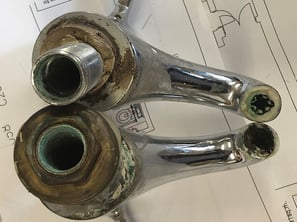

Also, how the parts are stored before installation will play a big role in the decision. If an item is stored properly, limiting the potential for contamination, then the amount of disinfection needed once installed can be kept to a minimum. Under such circumstances, a cleansing flush may well be sufficient!

If items have not been stored correctly and/or have become contaminated, then a disinfection of the installation should be carried out.

Conclusion

In essence, whilst there are no absolute correct answers, there may be some poor processes that if followed could lead to contamination. If you are uncertain as to the validity of the disinfection process being followed, you should seek advice from a competent source for the specific work.

Feel free to reach out if you have any questions about the issues mentioned above or if you would like to consult with one of our experts on water hygiene.

Editors Note: The information provided in this blog is correct at the date of original publication - February 2024.