BS 7592 has recently undergone a re-write which resulted in extensive changes. There are 3 new annexes with greater emphasis being placed on the competency of all involved in the sampling process.

BS 7592 – what has changed?

The changes include useful additional sections that detail sampling for investigations, for abrasive contamination and sampling for commissioning and recommissioning.

Three new annexes, two of which are normative, include sampling to investigate incidents and Legionella outbreaks in hotels and other multi-occupancy buildings, and sampling to investigate incidents and outbreaks in hospitals and healthcare.

The Informative annexe includes guidance on when to use respiratory protective equipment (RPE) and there have also been extensive updates to the guidance surrounding sampling plans.

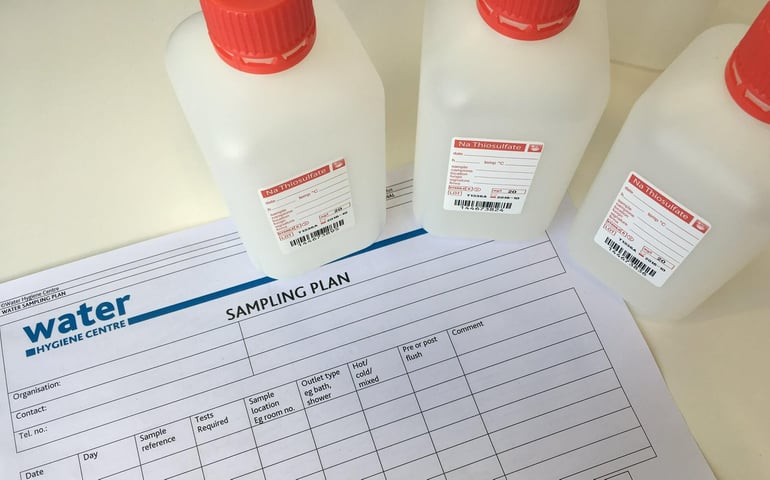

A sampling plan appropriate to the reason for sampling should be prepared and be based on a current site-specific legionella risk assessment. Sampling plans should also have enough detail to identify outlets to be sampled, for example, an up-to-date schematic diagram. The plans must also include the rationale for sampling and resampling, and the additional parameters to be taken at the time of sampling (e.g., temperature, pH, biocide level etc) to be agreed upon with the Responsible/Authorised person. If there is no water safety plan or Legionella sampling plan, then a site survey should be carried out to decide where to take samples, taking BS8554 into account

The updated standard now includes guidance on new installations and refurbishments, which was an area not covered in the previous document.

Also included is updated information and some changes to sampling hot water systems, bringing the standard more in line with HSG274, which considers multi-loop systems and hot water storage.

Another change is that potable water storage tanks should not be opened for routine sampling, as this increases the risk of introducing dust and other debris into the tank when the lid is lifted. To negate the need for this, routine sampling should be done from a dedicated sample valve point or the nearest outlet to the tank.

Section 7.4.1 also gives new guidance on routine sampling: For routine monitoring purposes, only pre-flush samples should be taken and, where possible, these should be taken from unmixed outlets.

Pre‑flush samples should be taken with no disinfection or adjustment of devices or inserts to obtain a reflection of the water as it is used.

Checks should also be made as to the type of analysis being carried out: are they sufficiently precise, repeatable, sensitive, and specific?

Other considerations

Pockets of potential contamination are often missed in areas of poor circulation or low flow if samples are only collected from sink outlets or showers as these areas are not subjected to the thermal disinfection process associated with passing through the hot water storage vessel.

Pockets of potential contamination are often missed in areas of poor circulation or low flow if samples are only collected from sink outlets or showers as these areas are not subjected to the thermal disinfection process associated with passing through the hot water storage vessel.

If you suspect a system is poorly balanced or has flow issues, samples should be collected from Legionella sampling or flushing points on each circulating loop and immediately before where the loop returns to the hot water vessel or calorifier as this is where the temperature is likely to be at its lowest.

The use of biocide neutralizing agents is discussed with EDTA no longer being the neutralizer to use when a copper/silver biocide is being used. Instead, ten times the normal amount of sodium thiosulphate (180mg/l) is recommended.

Conclusion

The updates to this document are significant, therefore it is important to make sure your processes are up to date to consider the changes and align with the new standards.

The previous edition of BS7592 was published in 2008. The world is evolving, technology and methodology evolve with it, so this revision is certainly due.

Feel free to reach out if you have any questions about the issues mentioned above or if you would like to consult with one of our experts on water hygiene.

Editor’s Note: The information provided in this blog is correct at the date of original publication – May 2022.

© Water Hygiene Centre 2022