Above all, three factors determine the likelihood of Legionella bacteria colonising a water system:

- Water temperature;

- Cleanliness; i.e. availability of nutrients and shelter;

- Water age; i.e. the rate of water movement & turnover within a system.

Much like a game of rock-paper-scissors no single one of these factors can trump the others in importance.

Legionella Control

Water temperature control is made more difficult in a dirty system where the temperature cannot penetrate the sediment or where the movement of water is restricted so that hot water cools and cold water warms up. A clean system is all very well, but if the water temperature is not controlled or if water is allowed to stagnate then bacteria will find a place to grow and biofilms will form.

Finally, even where water turnover is high, bacteria will find a place of shelter amongst sediment and sludge or hide out in pockets of the system that struggle to achieve the required temperature and adequate flow rates.

In most cases, the control of Legionella bacteria can be achieved by considering these three concerns and addressing any shortfalls in the design, installation, maintenance or operational performance of the water system. In this blog, we look at ways in which regular movement of water can be achieved.

Right First Time

“Right first time” has become a bit of a catchphrase here at the Water Hygiene Centre. Successful water safety begins with the correct design and installation of water systems. Failures at the first hurdle increase the inherent risk of a water system, and is, therefore, more troublesome, throughout its life cycle. HSG274 Part 2 states that:

“storage tanks, water heaters, pipework and components and associated equipment containing water” should be “designed to avoid water stagnation by ensuring flow through all parts of the system”.

Well-designed water systems that are properly installed and commissioned can minimise the potential for stagnation, which can be caused by a vast range of design and engineering defects, some examples of which include:

- Oversized storage vessels - in particular where there is more than 24-hour storage capacity;

- Uneven flow through parallel storage vessels;

- Oversized pipes or excessively long pipe runs;

- Pipework constrictions;

- Unauthorised isolation of services;

- Unbalanced hot water circulation;

- Standby equipment;

- Low draw-off outlets positioned at the end of the line e.g. water coolers or ice-making machines;

- over-provision of services resulting in reduced frequency of use.

Whilst operational estate managers may have the necessary authority and resources to correct physical defects, often, designers and project managers can address these defects either on the drawing board or at least before water systems enter service.

This leaves operational managers to devise and implement a programme of inspection and testing that will determine the operational temperature performance and hygienic condition of a water system; however, when it comes to identifying those outlets that are simply underused by the building occupants things start to become a little more difficult.

Infrequently used outlets

In the workplace, there may be outlets that are required for operational, welfare, or safety purposes that do not receive regular and frequent use and/or areas that are temporarily out of use. Estates managers require the assistance of building occupants to identify them, and whilst in some cases estates teams will have the resources to implement a Legionella flushing regime, in others this duty will fall to the building occupants themselves.

In the workplace, there may be outlets that are required for operational, welfare, or safety purposes that do not receive regular and frequent use and/or areas that are temporarily out of use. Estates managers require the assistance of building occupants to identify them, and whilst in some cases estates teams will have the resources to implement a Legionella flushing regime, in others this duty will fall to the building occupants themselves.

Any outlet that is subject to infrequent or intermittent use is classed as an infrequently used outlet. The definition of “infrequent use” may vary between applications and will depend not only on frequency and duration of use but also on other risk factors, such as water temperature and the vulnerability of the population that may potentially be exposed.

The Health & Safety Executive’s HSG274 Legionnaires’ Disease: Technical Guidance Part 2 states:

”Any outlet not used for a period equal to or greater than seven days” should be classed as an infrequently used outlet and that “for high-risk populations, e.g. healthcare and care homes, more frequent flushing may be required as indicated by the Legionella risk assessment”.

For healthcare premises, the Department of Health’s HTM04-01 Part B: Operational Management states:

“water draw-off should form part of the daily cleaning process. The procedure for such practice should be fully documented and covered by written instructions”.

HTM04-01 also states

“during the temporary closure of wards or departments, a flushing regime should be instigated to maintain system hygiene. Flushing should be continued until stable temperatures are achieved. Advice and guidance is also provided in BSI’s PD855468”.

According to PD855468, ‘hygiene flushing’ (i.e. drawing off water for the avoidance of stagnation) should be carried out weekly or “twice weekly in healthcare premises".

The Hierarchy of Control

Where infrequently used outlets are identified, it should first be established if the outlets are surplus to requirements. If no longer required, outlets should be removed – ensuring that all associated supply pipework is taken out and that no live dead-end pipework remains in situ.

Where infrequently used outlets are identified, it should first be established if the outlets are surplus to requirements. If no longer required, outlets should be removed – ensuring that all associated supply pipework is taken out and that no live dead-end pipework remains in situ.

Where this cannot be achieved, a regular Legionella flushing regime will be required.

Reasons for a Legionella flushing regime

Periodically flushing outlets can be an effective means of achieving a regular changeover of the water contained in the infrequently used outlet and its associated supply pipework, this ensures:

- Introduction of fresh cold water containing residual disinfectant, either from the mains supply or from a supplementary water treatment system, if fitted;

- Regular exposure of hot water pipework to temperatures at which Legionella and other bacteria are discouraged;

- Disturbance of biofilms through the sheering action of running water.

Process for flushing

A Legionella flushing regime should be devised as part of the organisation's “Legionella written scheme of control” or “water safety plan” and will need to take account of:

- The responsibility structure for management & execution of the programme including arrangements for holiday cover and absenteeism;

- The technical specification for the task;

- The task risk assessment & safe method of work, i.e. how to flush outlets safely;

- Process for identifying infrequently used outlets and keeping the list of outlets under review;

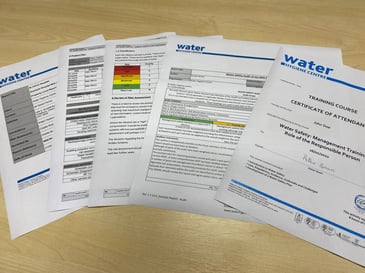

- Legionella training requirements for personnel carrying out flushing activities and those supervising them;

- Training and supervision of operatives carrying out flushing activities;

- Water safety record-keeping requirements.

The HSG274 Part 2 and HTM04-01 Part B guidance both advise that outlets should be flushed “until the temperature at the outlet stabilises and is comparable to supply water”. The time that this takes in practice will depend on a range of variables including:

- Length of the supply pipework;

- Ambient temperature;

- Frequency of use;

- Localised heat sources;

- Quality of pipework insulation

- Flow rate.

The list could go on… let’s just say the duration for flushing will vary between installations!

HTM04-01 adds that regular flushing applies to all infrequently used outlets and that monitoring water temperature when flushing to confirm that the temperature is comparable to the parent supply, which indicates that any standing water has been replaced with fresh water from the system.

Flushing Frequency

The guidance recommends that flushing is carried out at least weekly, but also suggests that Legionella risk assessments should be used to determine if flushing is required more frequently. For example, it is not uncommon in healthcare premises to find that the routine flushing of infrequently used outlets is carried out twice weekly or even daily where a particular risk has been identified (daily flushing is required in Augmented Care areas of a hospital).

Exposure to Aerosols

Water emitted from the outlet during flushing should be purged to drain safely. To reduce the risk of exposure to Legionella bacteria the British Standards Institutes published document PD855468 suggests:

“flushing should be carried out in a safe manner which minimises aerosol production e.g. removing showerheads prior to flushing”.

Water Hygiene Record Keeping

HSG274 highlights concerns that lapsed flushing programmes “can result in a critical increase in Legionella at the outlet”. Either hard-copy or electronic records are acceptable as long as they include details of:

- A list of the individual outlets to be flushed;

- The date, time and duration of flushing;

- The initials of the person carrying out the work;

- The water temperature achieved;

- Biocide concentration, if applicable;

- Any faults and other observations;

- Further actions required;

- Sign-off by an authorised person.

In addition to the flushing task records, all staff training should be recorded.

When can we stop flushing?

For occupied areas, checks should be made with local staff to ensure that the list of little-used outlets reflect current practices and usage levels. Outlets should be added and removed from the list as necessary. As such a regular review of the scheme and the list of outlets is required to ensure they remain up to date.

Management reporting procedures should be in place to ensure that flushing teams are kept abreast of changes in building and/or department occupancy.

Summary

The prevention of stagnation within water systems starts on the drawing board. Good design practices are essential to minimise resource-intensive control measures and remedial works later.

It might not sound difficult to flush water from a tap, and perhaps this leads to complacency amongst duty holders, but developing and implementing a dynamic and effective system for identifying infrequently used outlets can be difficult.

It requires ongoing leadership, communication, and cooperation throughout organisations to nail it down. In our experience, there is no “one-size fits all” solution, but organisations could start by identifying the key players and bringing them into the discussion. Including:

- Those who can provide information on whether outlets are used or not;

- Those responsible for administering & managing the flushing programmes;

- Those responsible for operational maintenance of the water systems;

- Designers and installers.

Some or all of these stakeholders may already be members of an organisation's Water Safety Group, which is the ideal forum for such discussions. We discussed the importance of a Water Safety Group and its functions in another blog.

Further reading is available> What are the definitions for 'little use' of an outlet?

Feel free to reach out if you have any questions about the issues mentioned above or if you would like to consult with one of our experts on water hygiene.

Editors Note: The information provided in this blog is correct at date of original publication - November 2019. (Revised August 2025)

© Water Hygiene Centre 2025